02 Sep April 2010

Willis Sinclair Homes

“The Lowcountry’s Premier Custom Home Builder”

Personalized Full-Service Construction

Fixed Price and Cost Plus Contracts

24 Gabriel Road

Lodge, South Carolina 29082

843 846 2500

April 2010

Henry, our fifth generation builder in double slings.

Henry has a couple of bad breaks …

One evening earlier this month, six year old Henry Ponds, Willis Ponds’ oldest child was swinging on a back yard swing set.

Somehow, (we are still not clear about the details), he ended up face down on the ground.

When we got him on his feet, both arms had dramatic, unnatural bends just above each wrist. Henry was hurting badly.

A couple of hours later, the diagnosis at the local emergency room was two broken arms. The anesthesiologist would not put Henry to sleep since Henry had eaten within 6 hours. So he had to wait until the following day.

The doctor put splints on both arms and scheduled surgery. The following day, all went well. Henry has two casts and several pins to hold everything nice and straight.

He got a big “thumbs up” at his one week check and now is out of his slings. In a few more weeks, he will have the pins removed. His doctor promises that will not be painful – Henry is not so sure. After that, the casts come off – just in time for summer break!

The nurse who helped Henry with his slings said he was the very first person she helped who had two slings.

Things are about back to “normal” (whatever that is).

From the desk

of Bill Burdick …

Silly me. I thought when all of my children reached adulthood in spite of bicycle wrecks, falls, accidents, miscalculated jumps and such, I was past emergency room runs. Henry reminded me that I am not.

This month we are discussing engineered building materials. There are those builders who don’t want to use any new materials and there are those builders who always use the newest materials.

At Willis Sinclair Homes, we carefully study new materials and use the ones that make sense. Obviously, some new technologies are often better than old ones. (Would you rather drive a Model T or a new Mercedes on a cross country trip?)

We look at materials from several view points. Is the material suitable for our application. How does the cost compare? Is it readily available? How much labor does it save (or cost)? Will the material weather and age well?

Once we are satisfied, we will begin to use the materials. We don’t follow crowds, we follow good engineering practices.

Call us and we will be happy to discuss engineered materials with you.

Bill

Vice President, Willis Sinclair, Inc.

Professional Engineer, Retired

843 846 2500

Engineered Building Materials

For years, builders have used locally available natural sawn lumber. Beginning about a hundred years ago, a new type of lumber appeared on the building scene. Engineered wood products have many advantages over non-engineered lumber including

-

It can be made for specific purposes,

-

Trees which are unsuitable for conventional lumber can be used for engineered materials.

There are many types of engineered materials. Obviously, we will touch on only a few of them in this newsletter.

Some of the engineered materials have significant disadvantages and those must be carefully considered before using the material.

At Willis Sinclair Homes, we stay on the forefront of building construction technology. We don’t use new materials just because they are new, however. Nor do we not use them becaue they are new. We use engineered materials where they make sense from a financial and structural view point.

Veneer based

Veneer based engineering materials are made by gluing layers or veneers together.

Plywood

Plywood is the most common and probably the first engineered lumber. There are many types of plywood. Hardwood plywood typically has hardwood on the two outer layers and pine on the inner layers. Marine grade plywood uses waterproof glue and has no voids on interior layers. Some plywood has a special water resistant coating on the top layer. We use this plywood for floors in our homes. Some plywood is tongue and grooved so it fits tightly together.

Typically, plywood comes in various thicknesses from ¼ inch thick to ¾ inch thick. Other thicknesses are available. Plywood is classified by the quality of the outer and inner layers and glues used.

Laminated Veneer Lumber (LVL)

Laminated Veneer Lumber (LVL)

Laminated Veneer Lumber is made basically like plywood. LVLs are used for long spans and where extra strength is needed. Typically, LVLs are about 7 inches to 16 inches wide. Typical thicknesses are 1¾, 3½ and 5¼ inches. Lengths are up to about 40 feet.

Parallel Strand Lumber (PSL)

Parallam or Parallel Strand Lumber (PSL)

A Parallam is basically pieces of veneer glued together. Typically, the lengths can be up to about 70 feet. The other dimensions are simply a matter of what sized lumber is glued together. The main advantage of PSLs is they will carry a big load and they can span large distances.

Glued Laminated Timber (Gluelam)

Gluelam

Gluelams are basically dimensional lumber that is glued together. They are often used in large open buildings such as church auditoriums and gymnasiums. Different kinds of woods can be used to fabricate Gluelams to give different appearances and specifications.

Particle Based

Particle based engineered materials are not made of veneers or thin layers of wood, but wood chips or sawdust and glue.

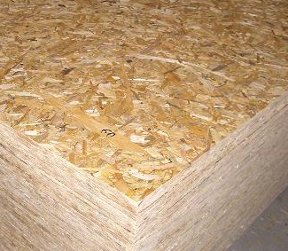

A pile of OSB panels.

OSB

Oriented Stranded Board is made in panels similar to plywood. Instead of being fabricated from veneers, it is fabricated from small pieces of wood. OSB is typically about 95% wood and 5% glue and wax. Some builders use OSB for wall and roof sheathing. Willis Sinclair Homes uses only plywood for those applications for reasons we will be happy to explain.

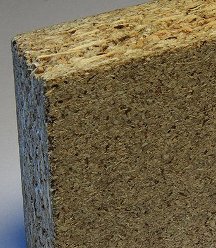

Particle Board

Particle Board

Particle Board is made from sawdust or very small particles of wood that are glued together. It is used typically in inexpensive furniture. Particle board is available in 4 x 8 foot sheets and thicknesses of ¼ inch to about ¾ inch. The board is very heavy and not overly rigid.

Fiberboard

Fiberboards are made from very small wood fibers as opposed to veneers or wood chips.

MDF

Medium Density Fiberboard (MDF) is made from breaking wood down into very small wood fibers. These fibers are then glued together under heat and pressure to form panels of materials.

Of course, there is a LDF (Low Density Fiberboard) and an HDF (High Density Fiberboard)

MDF is typically used for furniture and cabinets.

I-Joists

Wooden I-Joist

Wooden I-Joists are used to span large distances. They are made of a “web” of OSB and “flanges” of either dimension lumber or LVLs. As can be guessed from the name, I-Joists are often used as Joists to support floors.

Mineral Bonded

Although these are not wood products, they are engineered building materials

Cement Board

Cement Board, commonly called Hardie board is a molded cement and fiber board used for siding and other outside applications.

Gypsum

Gypsum, sheet rock or dry wall is another mineral board. It is used for interior walls.

Willis Sinclair Homes, where ‘Built Right’ is the only ‘good enough’ we understand.

Call 843 846 2500

No Comments