Mandy and Jessy are getting Colleton Coffee ready to open. This is the coffee counter. Mandy and Jerry (with a little help from me) built the cabinets and got the counter tops installed. The remaining counter top should be installed in a few day. No opening date has been set yet, but it will be soon.

From the Desk  of Bill of Bill

This has been a busy month at our home. Mandy and Jessy are opening a coffee shop (Colleton Coffee) in downtown Walterboro – just a few doors down and across the street from Twig, their boutique. The sink and RO water filter still need to be plumbed.

Mandy designed counters, display cases and book cases they wanted for the shop which will also sell books and small gifts. We purchased the materials and Mandy has been working diligently (along with her Brays duties and other tasks) to get the furnishings built.

Jerry, Will and I have lent a helping hand, but it has been Mandy that has done most of the work. Jessy has held down the fort at Twig.

All of this is going on while the Murdaugh trial is happening at the courthouse a few hundred yards from Twig. Fortunately, the downtown was not swamped with vehicles of those attending the trial as some predicted. The girls have a temporary coffee bar set up at Twig for those who want a snack and a cup of Joe.

If all goes well, Colleton Coffee should be open in just a few weeks.

There has been a lot of interest in a downtown coffee shop and bookstore in downtown Walterboro, so it should fill a need. If you are in the area, stop by and have a cup of coffee, have a snack and maybe pick up a book. The girls would love to see you. 252 East Washington Street, Walterboro. Also stop by Twig, their boutique at 225 East Washington.

Kandy and I are also planning a trip to visit our son and his family near the Springfield, Missouri area. Later in the spring, a grandson is graduating from high school near Knoxville and we plan to attend that ceremony. Our third trip this spring will be to see yet another grandson, also in the Knoxville area, awarded his Eagle Scout rank. It is quickly becoming a busy spring for us.

Steel

Normally homes, even large homes, are built with lumber. Often for longer open spans or other high stress areas, engineered lumber is used. LVLs look like thick pieces of plywood and are very strong. What happens when the span or load exceeds the capability of engineered lumber? The structural engineer typically calls out steel.

LVL

An LVL (Laminated Veneer Lumber) is an engineered piece of building material. Basically, it is a thick (often 1 ¾” or 3 ½” thick) and is available in heights which match common dimensional lumber (11 ¼ for a 2 x 12, for example). They are available up to 48′ in length and 24″ high. LVLs are much stronger than common dimensional lumber.

Keep in mind, the floor joist, beams and other elements have to be strong enough to not fail (obviously) and strong enough they don’t flex significantly. Support elements that flex too much give floors a “bouncy” feel. You have probably experienced walking on a floor where you could feel it move slightly or perhaps you were standing and could feel the floor bounce the smallest amount when another person approached you. Sufficient design eliminates bounce so the engineer has to consider not only over all strength to prevent a failure, but sufficient strength to prevent bounce.

We used a crane to set the steel framing on this home.

In addition to being more expensive than all wood framing, often using steel requires a crane to place it. In some cases, steel must be used for strength.

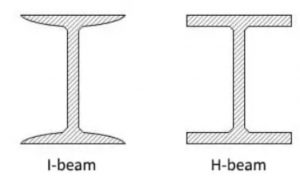

There are several ways an engineer can call out steel. Probably the most familiar is I beams (or H beams that have a wider flange). While steel is a very strong material, there are downsides. One is typically, a crane is needed to set the steel in place. Another detail is how do you attach the steel to the lumber framing materials. Drilling and bolting is a slow process, but what has to be done. Lumber can be attached with nails (using a special nail gun) to a steel member, but this takes more time than just nailing wood members in place.

Steel beams

There is a difference between I beams and H beams as you can see in this cross section drawing. There are also W beams which look similar to the H beams.

Steel members cost more than conventional dimensional or engineered lumber, but they are needed in some designs. Working with steel is also more difficult which adds to the cost.

Another factor to consider is how do you support the steel. Since the whole reason for the steel beam is to support a significant load, it needs strong columns to support it. Often these are square or round steel columns bolted to anchors in the foundation or floor. Sometimes, an engineer will call out stacked dimensional lumber (such as four 2x6s) to support beams.

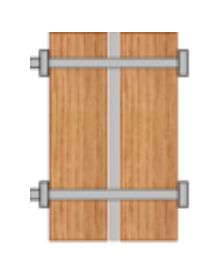

One way an engineer can select to utilize the inherent strength of steel is to design a flitch beam. A flitch beam is a flat piece of steel sandwiched between two pieces of dimensional lumber. A flitch beam can be easy to fasten to other lumber simply with nails. It is also typically lighter than an I beam, so often the need of a crane is not necessary. It is not quite as strong as an I (or H) beam, but is considerably stronger than wood and is a good option when wood isn’t strong enough.

A Flitch Beam

This cross section of a flitch beam illustrates how it is made. It has a steel plate sandwiched between two pieces of dimensional lumber. Bolts every couple of feet hold the beam together. Since there is wood on the beam, it is easier to attach to conventional framing.

Flitch beams are more expensive than engineered wood or solid beams. Obviously, if they are in an exposed area, they have to be covered since they don’t look like typical interior material.

Of course, all of the tie down materials we use are steel (straps, rods, bolts and cables), but those are not for load bearing applications (until high winds come along).

At Willis Sinclair, we use the best in materials available to build excellent homes. We will use steel if the structural engineer calls for it. We don’t cut corners – ever.

If you have any questions or comments, please call or text (843 846 2500) or email (info@WillisSinclair.com). We will be happy to discuss any questions or issues with you. No cost or obligation on your part, of course.

|

No Comments